Reverse engineering or back engineering is the processes of extracting the knowledge or design from an existing product and reproducing it based on the extracted information. Reverse engineering is used for creating interoperable products, but sometimes also for copying the existing objects. The methods of digital scanning and measuring enable cost-effective design and innovation process by using the new technology

Description of the tool

Methodology

By scanning it is possible to do reverse engineering as well as control the quality of the products within the production. The scanned files can also be used for 3D-modeling purposes for design, VR and additive manufacturing.

Case Study

Means of reverse engineering have been used for creating parts for existing products by scanning them. Metallic boat bodies were scanned within the TARGET-project to help company with quality control.

Objective of the tool

Outcomes Expected

More accurate and faster measurements of the products and product parts are acquired using scanners than the traditional measuring methods. Scanned files are easily convertible into VR-models.

Why Used

Using Digital scanning and reverse engineering is a time saving way of measuring. It is cost effective to scan the objects rather than measure them by hand. Also, the possibility of human errors during the measuring is minimized. Files can be compared to each other to verify the quality of products and suitability of parts.

Scope of the tool

Where Used

Depending on the size of the scanned object, a variety of scanners can be used. Small objects can be scanned basically anywhere. Large objects and buildings must be scanned on the location.

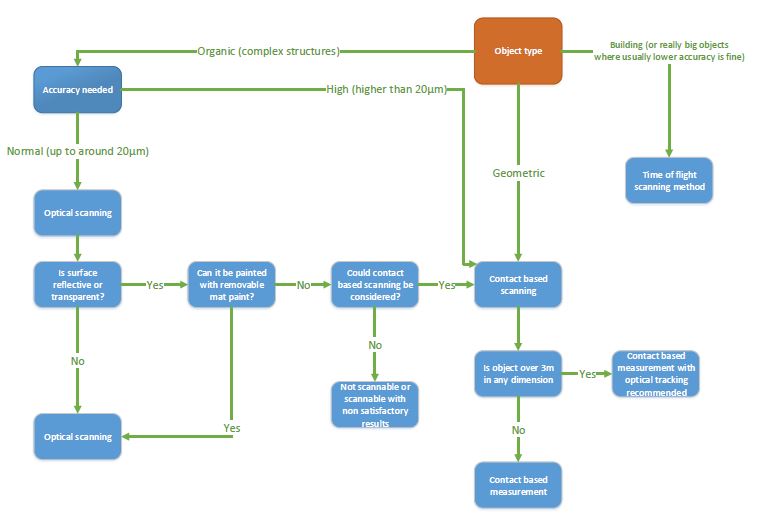

How Used

Scanning requires trained person(s), scanning equipment that fits for the specific purpose and also software. Software should be chosen based on wanted results from point cloud / measurement data (converting it to 3D/CAD model). Scanning itself can be easy depending on the equipment used, but post processing the data can take lot of time and training.

Deployment

Training

Mentor Skills/Training:

Knowledge of:

1. different technologies

2. usability in different cases

Equipment:

1. Scanner

2. High performance PC

3. Software

Materials – Train the Trainer materials, to train the mentors:

1. Scanning-Training material

2. Manuals (links to manuals)

3. Questionnaire for need

Tasks Assigned

Centria provides demonstrations and information about scanning and can provide education and training as a paid service. Measuring products and premises is also provided as a paid service. Centria can also provide information about the needed devices for a company willing to invest.

Downloads